In the vast realm of mechanical transmission, gears stand as one of the most brilliant stars. As core components for power transmission and motion control, gears—with their unique tooth profiles and ingenious meshing principles—form the solid framework of modern industry. They drive various mechanical equipment to operate efficiently and stably. From the powerful power output of car engines to the micro-motion control of precision instruments, from the orderly operation of industrial production lines to the execution of demanding missions in aerospace, gears are everywhere.They silently interpret the beauty of machinery and the power of engineering.

Gear principle of operation

The working principle of gears relies on a simple yet profound mechanical concept: gears achieve torque transmission and speed change through the mutual meshing of their teeth. When the driving gear rotates, its teeth sequentially push the teeth of the driven gear, thereby transferring power from one shaft to another. In this process, the gear tooth ratio determines the rotational speed ratio, enabling functions such as speed increase, deceleration, or equal-speed transmission.

Types of gear

- Parallel Axes Gears: spur gear, helical gear, double helical gear, gear rack, internal gear.

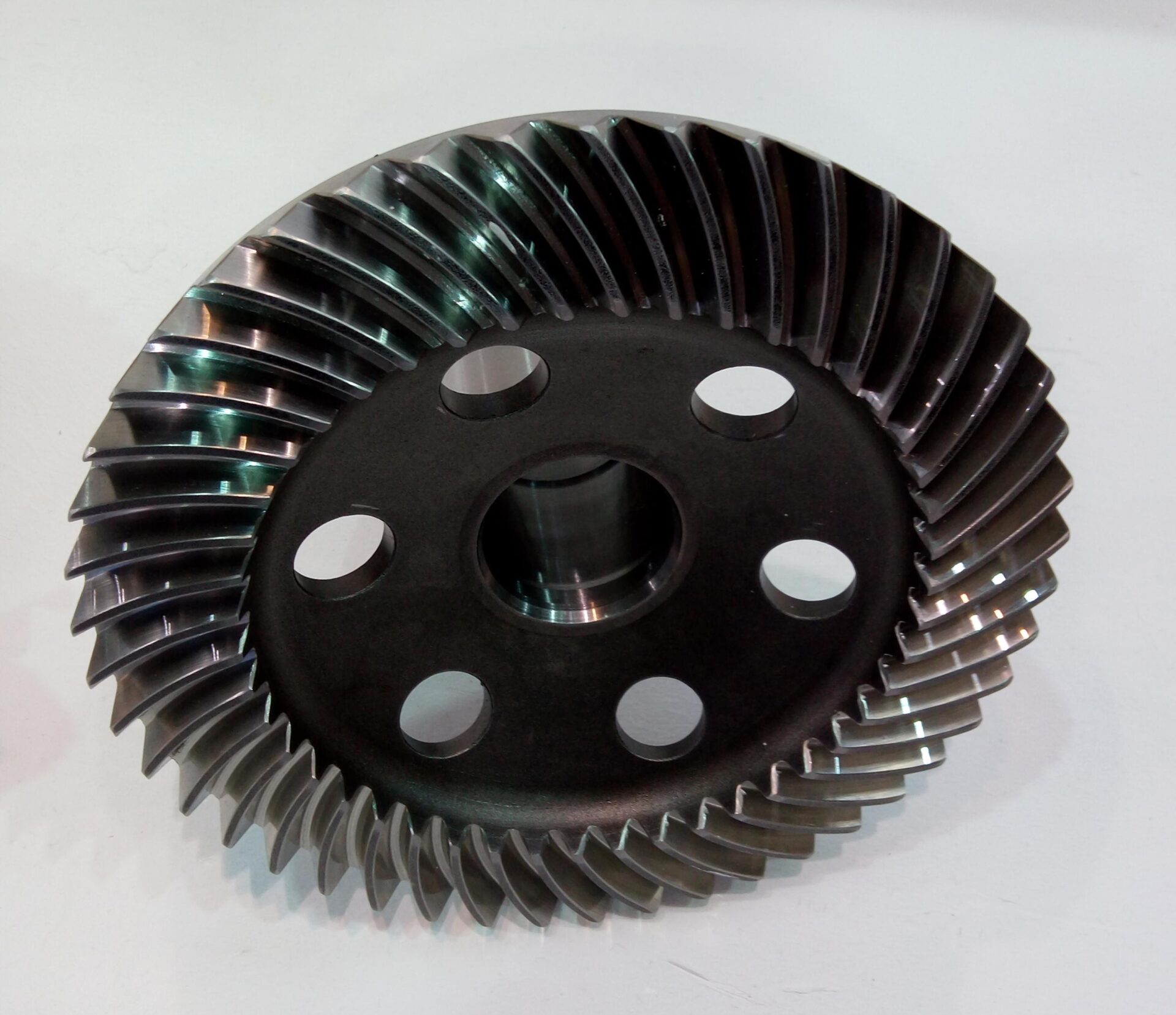

- Intersecting Axes Gears: straight bevel gear, spiral bevel gear.

- Crossed Axes Gears: worm shaft, worm gear, crossed helical gear.

Applications of gear

- In the automotive industry, gears are the core components of engines, transmissions, differentials and other key components, which directly affect the power performance, fuel economy and driving comfort of automobiles, and satisfy the transmission needs of electric vehicles in terms of high speed, high efficiency and low noise.

- In the field of aerospace, from the core components of aircraft engines to the flight control system of aircraft, gears maintain excellent performance and reliability under extreme temperature, pressure and vibration environments to ensure flight safety.

- In the field of industrial automation, gears, as the joints and transmission parts of various robots and automated production lines, provide a solid guarantee for the realization of high-precision, high-speed motion control, and promote industrial production in the direction of intelligence and high efficiency.

Manufacturing process of gear

- Usually choose high-strength alloy steel, stainless steel or special alloy materials to ensure that the gear has good mechanical properties and wear resistance.

- After forging, rolling and other thermal processing technology, the raw material is processed into a tooth blank with a preliminary shape.

- Advanced CNC lathes, milling machines, grinding machines and other equipment are used to turn, mill, grind and other precision machining of the tooth blanks, gradually shaping the precise gear shape and tooth shape.

- Through the surface treatment process, such as carburizing and quenching, nitriding, hard chrome plating, etc., in order to improve the gear surface hardness and abrasion resistance at the same time, to enhance its corrosion resistance, and to extend the service life of the gear.

YIZHI MACHINERY will always adhere to the development concept of “innovation-driven, quality first”, continuously increase investment in technology research and development, improve independent innovation capability, continuously optimize the product structure and performance, to meet the increasingly diversified needs of customers around the world with better quality products and services, and contribute to the development and progress of the gear industry. At the same time, YIZHI MACHINERY also look forward to working with more partners to create a better future, and jointly open a new chapter in the field of mechanical transmission.