In mechanical transmission systems, the tooth profile parameters of bevel gears directly determine their load-bearing capacity, transmission efficiency, and service life. A reasonable tooth design not only improves running smoothness but also effectively reduces noise and vibration. So, how exactly do these key tooth parameters affect transmission performance?

Key Tooth Profile Parameters and Their Impacts

Module

- Function: Modulus is a key tooth profile parameter affecting the load capacity of bevel gears. Determines tooth size and load-bearing capacity.

- Effect: The larger the modulus, the thicker the teeth and the greater the load-bearing capacity, but may increase weight and inertia.

Pressure Angle

- Function: It determines the shape of the tooth profile, affects the contact stress and transmission efficiency of the tooth surface.

- Effect: The size of the pressure angle will affect the distribution of the force on the gear. Higher angles improve load capacity but increase axial forces.

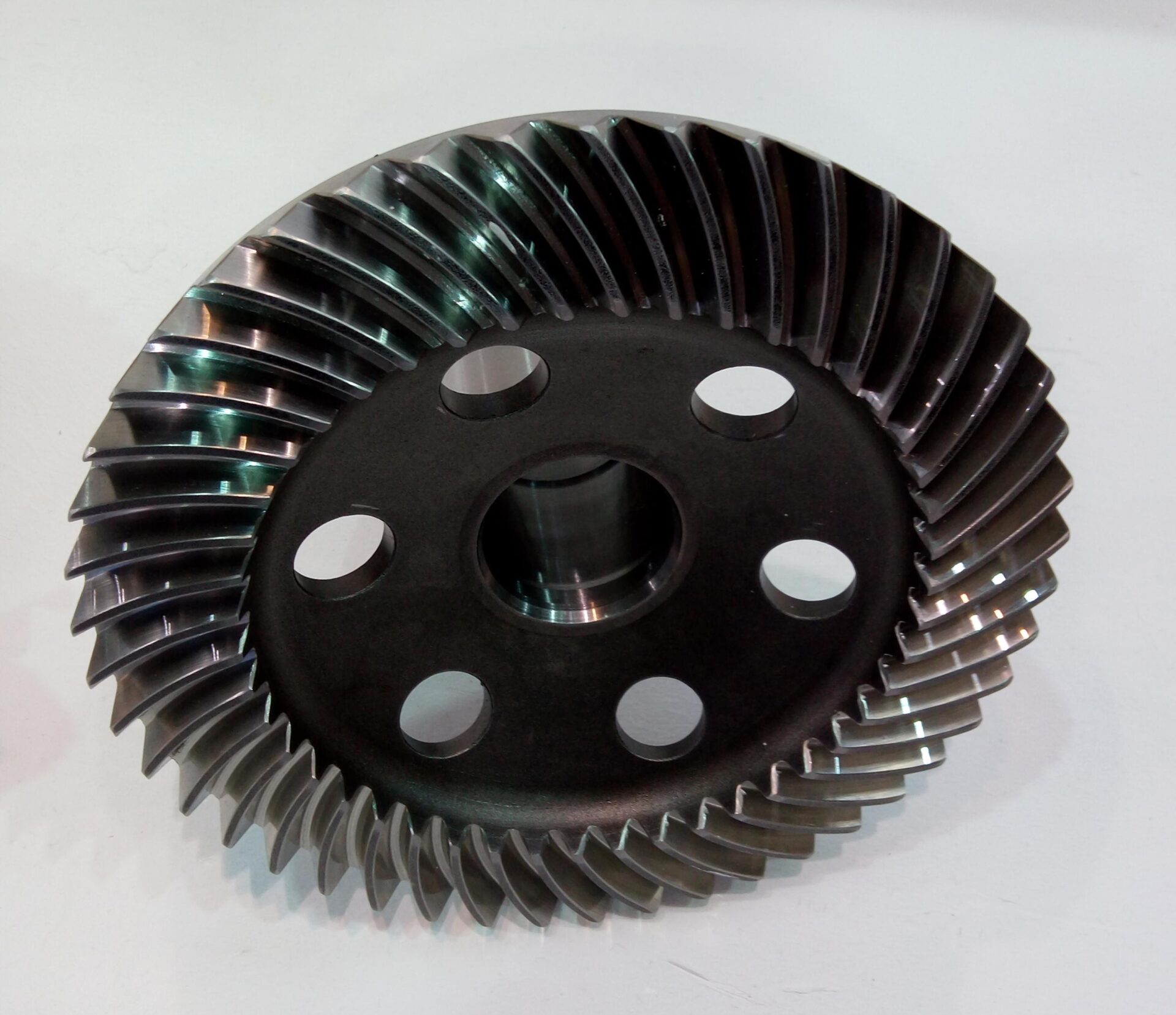

Spiral Angle

- Function: It is a unique parameter of helical bevel gears, which can improve the smoothness and load-bearing capacity of gear transmission.

- Effect: The appropriate helix angle can improve the meshing of the gear, reduce the meshing loss, and improve the transmission efficiency, but if it is too large, it will increase the axial force, which will reduce the transmission efficiency.

Face Width

- Function: It affects the bearing capacity of the gear and the smoothness of the transmission.

- Effect: Generally speaking, the larger the tooth width, the stronger the bearing capacity, but if the tooth width is too large, it will reduce the bearing capacity of the gear, but it will also increase the weight and cost of the gear.

Practical Significance of Optimal Selection

- High-load applications (e.g., heavy machinery): Prioritize large module and pressure angle designs.

- Low-noise requirements (e.g., automotive differentials): Optimize spiral angle to minimize vibration.

- Space-constrained uses: Achieve efficient transmission through parameter optimization.

Bevel gear selection requires balancing load, speed, space, and cost factors. Scientific parameter matching enhances transmission efficiency and extends service life, providing critical support for equipment performance optimization.