Appearance: key-shaped vs. sawtooth-shaped

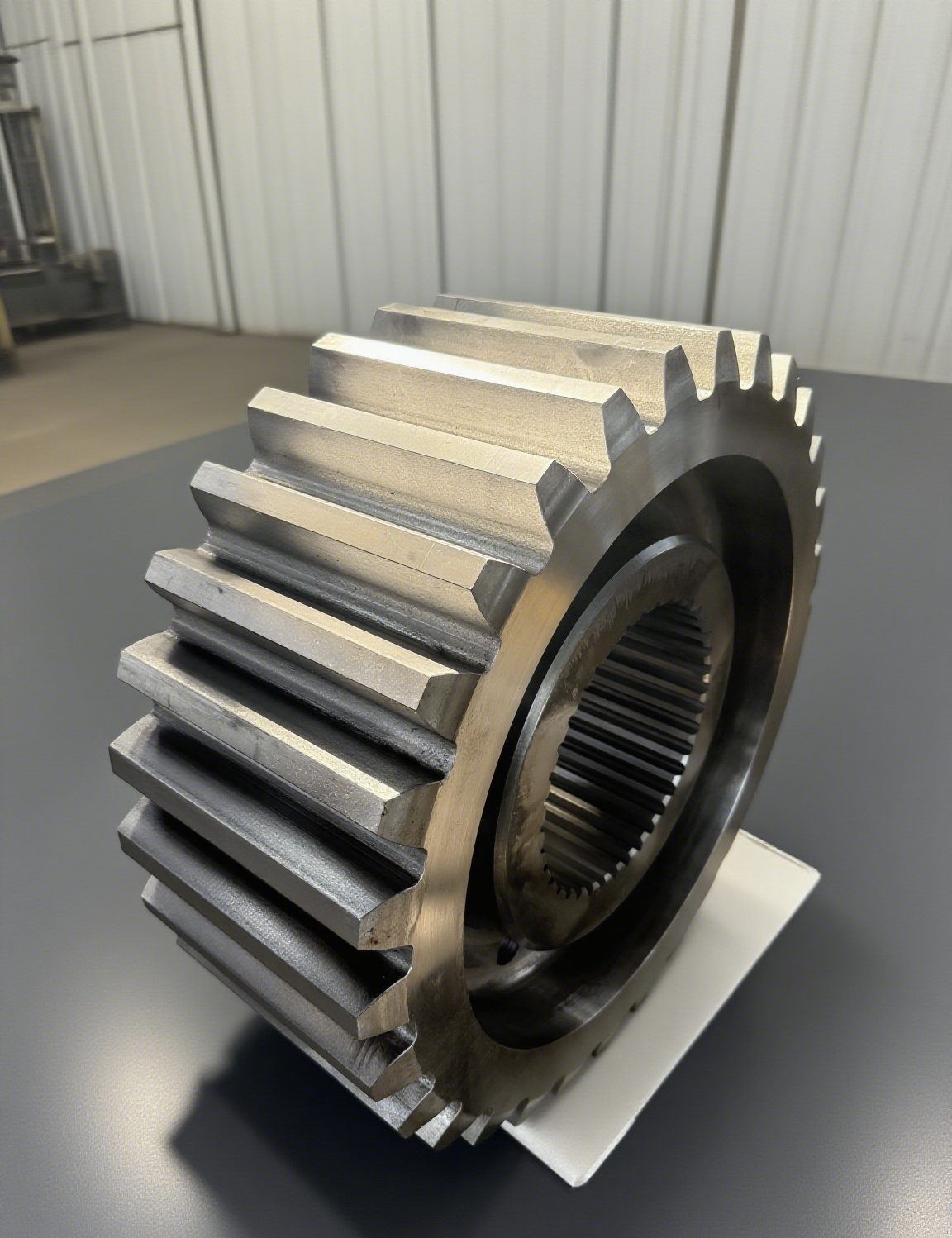

Spline shaft: Like a bunch of keys on a key ring (such as the keys for old-style security doors, which have multiple grooves and ridges on the side).

Example: The drive shaft of a tractor has longitudinal grooves and ridges on its surface, similar to the ridges on a chocolate bar, which are used to grip other parts and prevent slippage.

Gear shaft: Like teeth carved directly onto a sausage (such as the gears on a bicycle chain).

Example: The rotating head of an electric drill, with gear teeth directly on the shaft, used to mesh with other gears to transmit power.

Function: anti-slip vs transmission

Spline shaft: Mainly solves the problem of ‘how to lock tightly without loosening’. Just like the convex and concave grooves of a USB plug (spline shaft) and a computer interface (spline hole) aligning, once inserted, it will not rotate randomly.

Example: The gearshift lever in a car’s transmission. The spline shaft allows the gearshift lever to slide and shift gears but prevents it from disengaging.

Gear shaft: Primarily addresses the issue of ‘how to drive others to rotate’. Like two interlocking gear toys, when one rotates, the other must follow.

Example: The gear shaft in a clock directly drives the hands to rotate.

Movement method: sliding vs. biting

Spline shaft: Allows parts to slide along the shaft, but must rotate synchronously.

Example: The pneumatic rod of a lift office chair allows the chair height to be adjusted (sliding), but does not rotate when seated (splined anti-rotation).

Gear shaft: Must be fixed in meshing with other gears and cannot slide.

Example: The pedal shaft of a bicycle meshes with the chain, and pedalling drives the rear wheel to rotate.

Load characteristics: torsional resistance vs shear resistance

Spline shaft: Specialises in withstanding torsional forces (such as the force of tightening screws). When tightening screws with a screwdriver, the splined shaft acts like the edges of the screwdriver, preventing slippage.

Gear shaft: Specialises in withstanding meshing forces (the compression between gears). Like tightly clenched teeth, the gear shaft is one of the teeth, and it must not break when biting down hard.

Common application scenarios

Spline shaft:

- Automotive transmission systems (such as drive shafts)

- Adjustable components in machine tools (requiring sliding + anti-rotation)

Gear shaft:

- Power transmission in reduction gearboxes (such as motor output shafts)

- Wheel shafts in toy cars (directly driving the wheels)

A spline shaft is a ‘slotted rod used to grip things and prevent slippage’, while a gear shaft is a ‘toothed rod used to mesh with others and rotate together’. It’s like the difference between a key and a serrated knife—one relies on convex-concave matching for fixation, while the other relies on teeth for cutting and transmission.