In mechanical transmission systems, bevel gears are the key components used for intersecting shaft transmission. Among them, spiral bevel gears and straight bevel gears are the two most common types. Different gear designs are suitable for different working conditions. Choosing the appropriate gears can significantly improve transmission efficiency, reduce noise, and extend service life.

1. Structural Characteristics

Straight Bevel Gear

- Shape: The tooth surface is straight, and the tooth direction is parallel to the generatrix of the bevel surface.

- Engagement Method: Single tooth engagement, the contact line is a straight line.

- Manufacturing Process: Relatively simple, usually processed by milling or gear broaching.

Spiral Bevel Gear

- Shape: The tooth surface is a spiral curve, similar to the version of bevel gears with helical teeth.

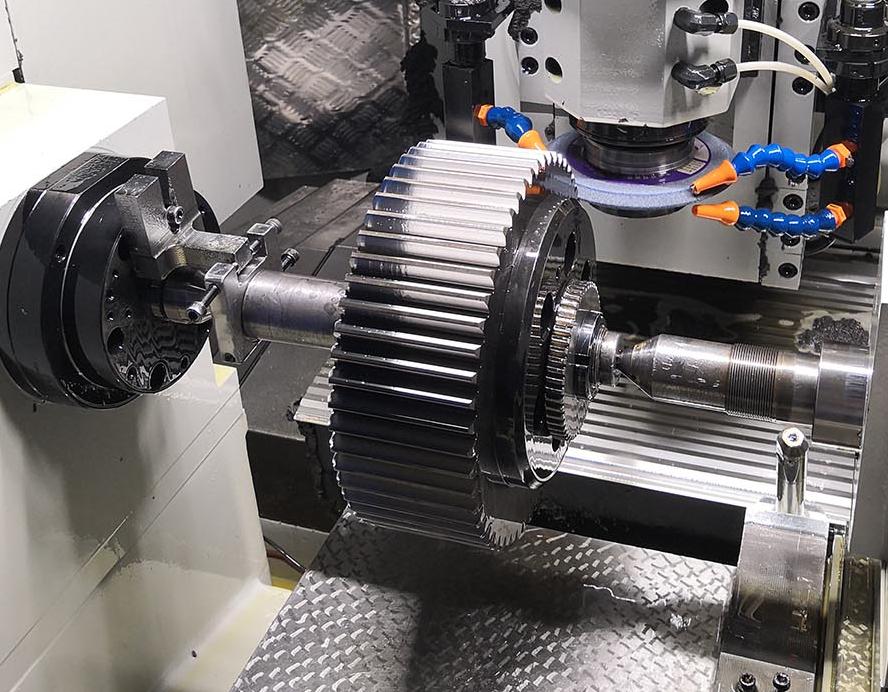

- Engagement Method: Multiple teeth engage simultaneously, with a larger contact area.

- Manufacturing Process: Requires special machine tools (such as Grisson machine tools) for processing, with higher costs.

2. Performance Comparison

| Comparison items | Straight bevel gear | Spiral bevel gear |

| Transmission smoothness | Lower (single tooth engagement, high impact) | High (multiple tooth engagement, smooth operation) |

| Noise level | Higher (clear engagement impact) | Lower (helical teeth reduce vibration) |

| Load capacity | Lower (contact area is small) | High (contact area is large, distributed evenly) |

| Efficiency | 95%-98% | 98%-99% |

| Manufacturing cost | Lower (simple processing) | Higher (requires precision machinery) |

| Axial force | Smaller | Greater (requires thrust bearings for support) |

3. Application Scenario Analysis

Straight Bevel Gears

Low-speed, light-load transmission:

- Manual tools (such as drilling machines, grinding machines)

- Agricultural machinery (such as harvesting machines)

- Low-cost equipment (such as toys, small household appliances)

Situations requiring simple maintenance: Due to their simple structure, straight bevel gears are easier to install and replace.

Spiral Bevel Gears

High-speed, heavy-load transmission:

- Automobile differential (such as the transmission system of rear-wheel drive vehicles)

- Industrial gearboxes (such as mining machinery, wind power gearboxes)

- Aircraft engines (high rotational speed, low noise requirements)

High precision, low noise requirements: Due to the spiral tooth design, the meshing is more stable, making them suitable for precision equipment.

YIZHI MACHINERY can offer customized solutions for bevel gears, whether they are spiral bevel gears or straight bevel gears. We use high-precision processing equipment to ensure the durability and transmission efficiency of the gears.