Description

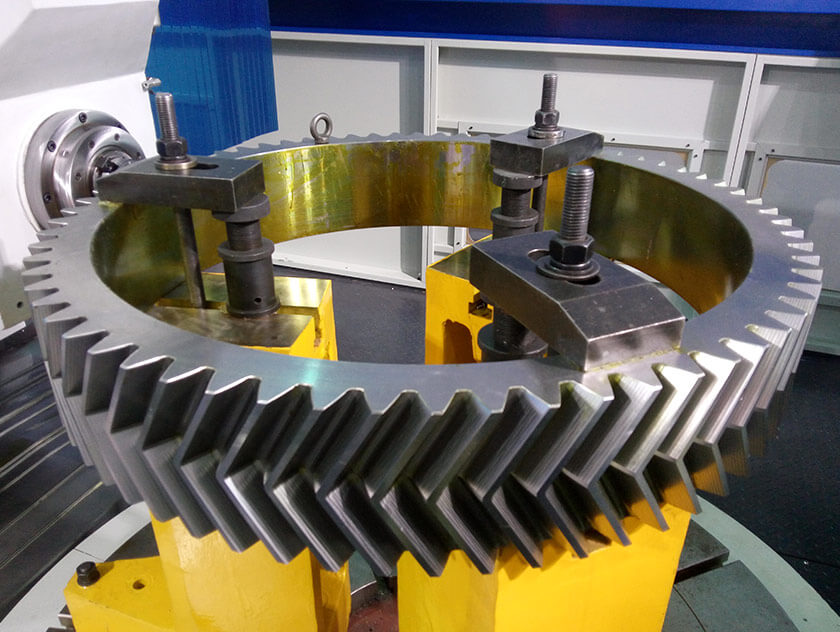

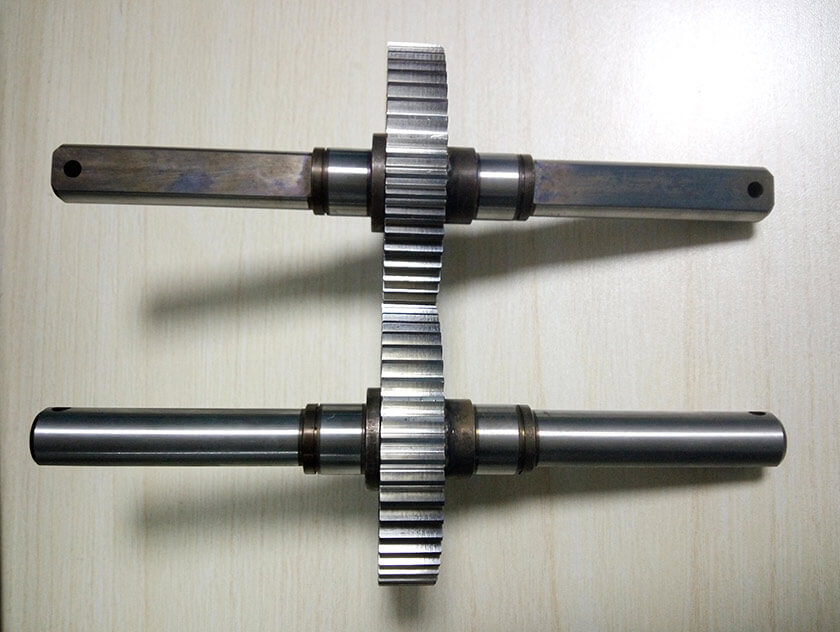

A girth gear is a large annular gear employed in heavy machinery and industrial equipment, primarily utilised in large rotating apparatus such as rotary kilns, ball mills, and rod mills. By meshing with a pinion gear, it transmits power to the large rotating cylinder, thereby ensuring the smooth operation of the equipment.

Technical Data

| CHINA/GB | ISO | ROCT | ASTM | JIS | DIN |

| 45 | C45E4 | 45 | 1045 | S45C | CK45 |

| 40Cr | 41Cr4 | 40X | 5140 | SCr440 | 41Cr4 |

| 20CrMo | 18CrMo4 | 20ХМ | 4118 | SCM22 | 25CrMo4 |

| 42CrMo | 42CrMo4 | 38XM | 4140 | SCM440 | 42CrMo4 |

| 20CrMnTi | 18XГT | SMK22 | |||

| 20Cr2Ni4 | 20X2H4A | ||||

| 20CrNiMo | 20CrNiMo2 | 20XHM | 8720 | SNCM220 | 21NiCrMo2 |

| 40CrNiMoA | 40XH2MA/ 40XHMA | 4340 | SNCM439 | ||

| 20CrNi2Mo | 20NiCrMo7 | 20XH2MA | 4320 | SNCM420 | |

| 17CrNiMo6 | |||||

| 18CrNiMo7 |